Bending Aluminium Extrusions to a Template

In the past we’ve discussed what references we bend to. Today we will discuss in detail the benefits and drawbacks of bending aluminium to a template, including ways to improve your template to ensure the best possible results.

Benefits of Using a Template When Bending Aluminium

Templates are a simple way to plot out what shape a bend needs to take. It is quite easy to cut out a shape to fit the required space without the need for specialist plotting software.

Quick and Easy

- Templates can be quickly assembled with little to no hassle.

Reusable

- Depending on the material, templates can be used multiple times and stored for future use without much risk of damage or wear over time.

Great for When Measurements Are Not Known

- Especially useful during refurbishing, as spaces for replacement aluminium windows, doors, and other components are not always symmetrical or exact. A template can reflect irregular shapes accurately without complex measurements.

Useful as Checkers

- Templates can serve as their own checking tools, allowing the final product to be verified directly without creating additional checkers.

Template Drawbacks

Accuracy Is Limited

- When hand-making templates, small mistakes can lead to uneven or ragged curves. Inaccuracies in the template can carry over to the final product, so care must be taken to ensure precise shaping.

Bend Difficulty Can Be Overlooked

- When working from a physical template rather than a drawing, it’s easier to overlook complex bend areas that might otherwise be detected earlier in the design phase.

Freeform Shapes Are More Difficult

- Certain tight-radius shapes cannot always be produced with specific profiles, and these limitations may only become apparent once the profile is delivered for bending.

The Material Used for the Template Can Affect Accuracy

- Metal: The most accurate and durable option, as it resists deformation.

- MDF or Wooden: A reasonable choice, though edges can splinter and affect precision over time.

- Paper: The cheapest but least accurate and durable option. Suitable for small projects only. Laminating the paper can extend its lifespan.

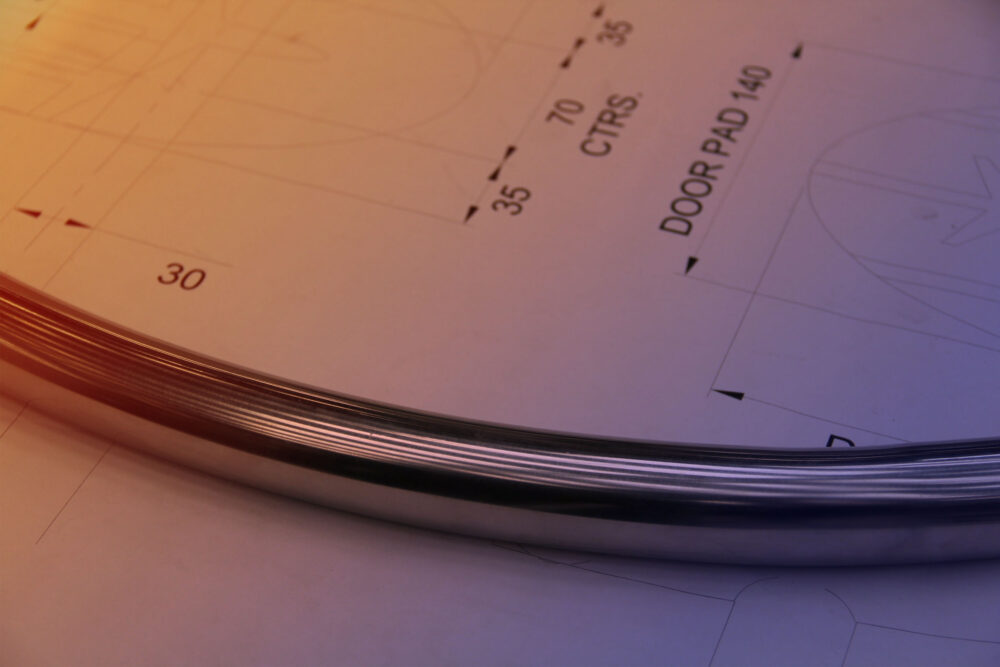

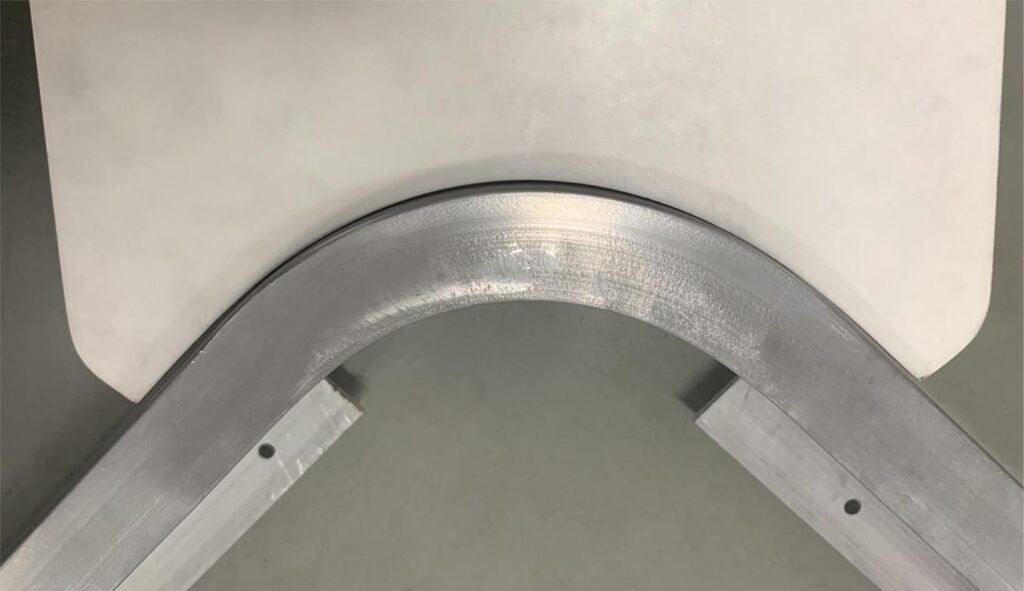

How We Use a Template

Bending to a template requires a more hands-on approach than bending to a full technical drawing. This method is still highly effective but needs specific handling techniques.

Bend to the Inside Edge

- When bending to a template, we always bend to the inside edge unless otherwise instructed. This ensures consistent checking and reliable accuracy.

Work to a Smooth Curve

- Unless otherwise requested, we prioritize smooth curves over jagged or damaged template edges to maintain high-quality, consistent results.